Thursday, September 10, 2020

Monday, August 24, 2020

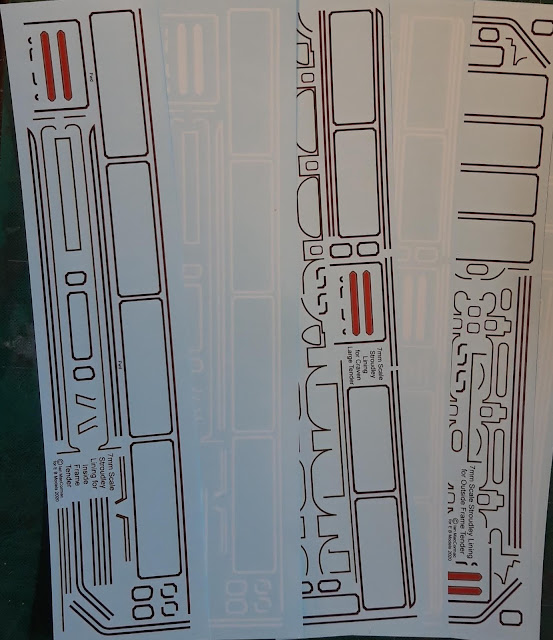

Carriage Smoking transfers

I will print two styles in 4mm and 7mm.

£5 per sheet for 4mm and £8 per sheet for 7mm. Postage to UK included.

and the photo below is of the actual transfer, I have reversed the whole thing so it can be put on the inside of the 'glass' as a transfer. Quite difficult to photograph! Cheers, Ian

Just tried applying some of these and because they are on the inside, I have also just put these onto a piece of clear plastic along with some other bits for the saloon carriage windows I drew at the same time, about a year ago, when I was trying to get things printed and failed. These are now printed with the Ghost white toner on the HP LaserjetPro M254dw that I purchased so as to be able to move things on. They seem to work nicely. I have used Microsol to bed them in a bit but didn't really see any difference from plain tap water.

The sheets above are 4mm, the examples on the clear plastic sheet are a mixture of 4mm and 7mm scale. The Smoking Carriage was used on the long window thirds of the Stroudley 4 wheelers in case anyone was wondering!

Renamed and renumbered 7mm Dapol Terrier

Just been trying out the names and etched plates to rename and renumber a Dapol 7mm Terrier that had been Brighton with the gold medal lettering. I used a curved scalpel blade, very gently, to scrape away the wording and name off the existing tank side and removed the plastic numberplate by just putting the tip of the blade under it and twisting very slightly.

I then applied a very thin coat of Vallejo 70.510 gloss varnish using a broad brush and waited for it to dry - about 20 minutes.

Next was applying the white underprint layer, to ensure there is white in the final name and to allow the coloured toner to show as if printing on white paper - which is what the printer is designed to do.

The next time I do this, I shall experiment with Microsol or Microfix decal solutions to see if the edge of the transfer can be softened further. I will also try another type of gloss varnish to see if it makes the carrier film disappear better. The white was allowed to dry - again about 20 minutes. I did the other side whilst waiting and filed and smoothed the tabs off and painted the etched plates a dark blue and used a black sharpie marker to put the lettering in before a rub over with abrasive paper to leave them as per the photo below.

Then another thin coat of the gloss varnish over the white to seal that, let it dry before then applying the coloured part of the name. Another thin coat over the dried coloured name and a tiny drop of superglue for the etched number and works plate and I am ready to reassemble the parts for the photo. I am correcting the position of the cab gauges and a few other detail improvements also. I will post a photo when I have completed all those, later.

The lighting that the photo is taken in really affects how the IEG looks doesn't it!

I can supply any 7mm name for a Terrier as well as the etched plates as shown here and below. £18 including postage.

Above are the names just printed on white paper with the etched number and works plate alongside. I do have another for 36 Bramley if anyone wants one by the way.

Now that I have got the names sorted for 7mm I am going to start development work on the Stroudley lining and lettering for 4mm, which I know a few people are waiting for! The number and works plates are all available already, as they are for any 4mm loco with numberplates and the works plates for the I3 class are also available as per the October 2019 post

Cheers Ian

Monday, August 10, 2020

Loco and tender transfers for Stroudley Passenger Lining, in 7mm scale presently

I have been drawing more Transfers for the last week.

For the loco lining, I am doing each loco

separately at the moment with a few spare bits on each sheet, going through all

the EB Models offerings and some others I need also. So far I have the G Class, D and

E tank locos, Stroudley inside and outside frame tenders and Stroudley lining for the large Craven tender completed.

I am drawing over scans of etches so they

are designed to fit.

The photos show the E1 back left, D1 back right and G to the front of the top photo and the bottom photo shows the Stroudley inside frame, large Craven tenders and Stroudley outside frame from left to right.

I have Richmond class, Belgravia class,

18/21 and Dieppe and Grosvenor scanned. The Richmond will include some extras to fit the B1

from Albion or it may be a completely different sheet depending on what I can fit on, and there will be an E4 and E5 that I still need to scan.

I will also do a Terrier and anything new

so that they can be completed.

About a third of the names have now been sorted, and

I will be doing them all and printing to order for those to go out with the

lining. Same two layer application. I haven't printed any of those yet.

I will also be offering a 'finishing service' of lining, name and etched number/work plates, when the etchers have got back to their normal two to three week turnaround rather than the eight it is taking at the moment.

I have not yet set any prices but am trying to keep it to something like £12 per loco or tender. I will also need to get the 4mm versions drawn up - I shall make the white and red lines a little thicker than scale thickness otherwise I don't think they will show at all. The white or red lines on the main loco body lining is 0.073mm thick in 7mm and can be seen okay but if that reduces to 4mm scale, the line will be only 0.042mm thick which is pushing the technology a bit too far I fear. I shall put some experiments up on here to see what others think.

Comments always welcome.

Cheers, Ian

Thursday, July 23, 2020

Carriage Transfers in 7mm, 4mm and 2mm scale and 4mm scale Springs for scratchbuilders

Chris Cox reminded me last week and I found the etches underneath everything else!

There are two styles, I have called them Craven and Stroudley. Slightly different shapes.

Fives different sizes: 2'6", 3'0", 3'6", 3'9" and 4'0".

£24 the sheet incl postage. Only a couple available but I can get more if demand is high.

Carriage transfers:

I bought a laser printer and a white toner. This is a £200 printer, it doesn't have the position repeatability of a £12,500 machine so for the colours to show up on a dark background, the transfers are put on in two layers. A white layer under a coloured one. Waterslide.Sunday, June 28, 2020

3D printed resin parts for the E B Models 7mm Stroudley rebuilds of Ex-Craven Singles 2-2-2 Dieppe Class

Other 3D printed resin parts for E B Models 7mm loco and tender etches

Richmond class loco first.

I have also been asked to do an E1 cab interior for someone, the front cab boxes were in his kit, I could add these if requested. £27 including postage.

Wednesday, June 24, 2020

EB Models sets of 7mm scale 3D resin prints for Locos

This is currently the case with the 4mm Slaughter Goods loco and tender.

The parts have been designed and printed and I am compiling these ready for sale.

I present the 3D prints for Stroudley's 18/21 tank engine first.

The above shows the 3D pictures from 3D design software and below is a photo of the 3D resin printed parts in the same orientation.

As I get others organised, I shall add them here. I have completed the design and printing for:

the Craven single Dieppe and others; Belgravia class; Richmond D3 class; the 18/21 tank as above; Craven tenders; Stroudley Outside frame tender; Stroudley Inside Frame tender.

I shall hopefully get these on here during the next couple of days.

All are available for purchase through E B Models. The price will be as per the E B Models website which is currently £60 for a set for a loco, £50 for a set for a tender with a £5 reduction if the etches are ordered together with the fittings for a loco and tender. All plus postage. See the website for the latest prices, E B Models website.

Hope all are well and the modelling has been going well. Cheers Ian

Friday, May 15, 2020

Wheels for the 4mm Slaughter Goods

Just seen this in the last few days and a set arrived today. Just like Mike used to make!

Also, Phil has used a High Level Roadrunner+ gearbox with a D2 extender and a new style1015 motor.

Cheers Ian

Sunday, April 26, 2020

Getting ready for paint and transfers

Finally got around to filling the join in the boiler, fitted a couple of other small parts and designed the lining, numbers and cartouche for the transfer for the side sheet. Cheers Ian

Thursday, April 23, 2020

Accomodating 'finescale' wheels meant a complete rethink on the boiler!

Sunday, April 12, 2020

On its wheels!

Saturday, April 11, 2020

153 continues, start of the loco body etc

So, I realised I needed to design and print a lot of parts for the loco before I could finish this, so that's what I have been doing, whilst starting to solder some parts together. Here are the front buffers and bufferbeam, smokebox, smokebox cylinder lubricator, weird thing at the rear of the chimney(anybody know what it might be?), the chimney, clack valves, dome, salter spring, axleboxes, springs, whistle, firebox with backhead, safety valve both inner and outer, the main part of the footplate and outside frames soldered together, the top of the motion plate soldered, then the front splasher, driving splasher, cab front and sidesheets. I have a boiler to roll also and managed to get the brackets to fit the cab front to and a couple of handwheels onto the firebox top as well as the sight glass, regulator handle, and firebox door etc onto the backhead all part of the same print. I have started the chassis also and am trying to get all the soldering sorted before gluing on all the prints. Oh, and a photo of what I am trying to make!

Cheers Ian

Sunday, April 05, 2020

153 next and trying to get other bits completed ready for paint.

I didn't manage to get the 7mm Slaughter Goods to the etchers so I am doing what I do have.

3D printing is also just for my bits at the mo as I am almost out of IPA to clean the resin prints with, wish it was the beer as I can still get that!

So I drew the tender parts in 3D after assembling the etched parts I will include in the revision of the etches.

Thursday, March 19, 2020

Slaughter Craven Goods – clearing up some of the instructions

Slaughter Craven Goods – clearing up some of the instructions

Phil has pointed out there is no precise position for the motion plate mentioned anywhere. It should be 3'8and a quarter inches in front of the middle axle ie 14.75mm in 4mm scale.

Hope this part of the GA helps.

Mike has been asking some questions and so I thought others of you would also be doing this over the next few weeks so I am, in the greatest Waldron tradition, placing an addendum to the instructions here, as it happens. My responses in red.

Hi Ian:

Good day yesterday.

Ive just been trying to get my head round the copious instruction diagrams. Puts mine to shame!! They were only b&w, but I did put arrows in!!

On the ‘Loco Chassis Parts Location‘ page, the white piece above the letter ‘A’ in the green circle looks like being a motion plate(?) with 5 square holes each side ... presumably for cylinder slide bars?

Is that a residue from intended etched slide bars, maybe changed your mind?

I note you mention a drop in set of motion parts for the future. Presumably the etched version you produced for the C class a few years ago isn’t that?

Bravo for a super-detailed kit!

Mike

Hi Mike

The parts above the A are the rear of the cylinder block and the parts above the B are the motion plate. The white is just the rear of the etch, being blank, and the drawing of the etch sheet to the left of the diagram should show what is what. The parts above the A, once added together, by soldering or whatever other means, are then turned through 180 degrees so the detail parts are to the rear and then get put into the chassis at the rear of the cylinder casting position. Yes the rectangular slots are there to help people who realise this is for a representation of the slide bars and some parts of the etch edge are the correct size to cut up and put in those rectangles and meet the motion plate front part – the parts above the B – but as you rightly say, there is in development a drop in part for this which will likely be available some time this year or next.

I hope that clears it up.

Still at David’s in Kent so cannot use the actual artwork to check but I think what I have said above is correct.

Many thanks

Ian

Thanks Ian

That makes sense now.

Is there either a piece on one of the frets should one choose to close it up to form the block, or introduce a home-made item?

Hi Mike

There is a front and a rear to the cylinders but I didn’t think anyone would bother putting the underside of the casting in as I was using the hollow parts to solder the compensating beam for the front axle inside the cylinder space so it wouldn’t show.

Cheers

Ian

Sorry to add one more question....

Can’t work out how the etched loco spring shape related to the printed ones .....

Mike

The etched spring is the driving wheel spring inside the splasher, over the inside frame. See the photos

Oh ok.

I can just see a corner on the top left photo peeking out! Not really visible on the others.

I’ll check my own collection of photos.

I’ll leave you in peace!

M

Loco body parts location diagram 3 show where to put them if you can get the space.

Cheers

Ian

The tender coping ... is it curved horizontally or a simple ‘straight out’ angle?

The pictures suggest curved.

Looking forward to getting building after my mate and I have rebuilt my crumbling garage!!

New roof being fitted, to protect lathes, milling machine & tool grinders from the storm rainwater ingress & flooding (not river!) I’ve been fighting all winter, but found parts of the walls crumbling! It was only built in the early 60s.

Sorry I’ve got some more points I’m unsure about re Slaughter goods:

1. Are the tender copings flat or curved when viewed from the front/rear?

2. Are the coupling rods pivoted on the crank pin or knuckle joint?

3. There are 2 holes in the loco-tender drawbar - which should be used for P4?

4. Where do the two little c45degree cranks attached between the water tank top and holy (4 hole!) inner tender panels fit?

5. I assume the 2 little T shapes on body sheet 2 are lamp irons?

6. The two 45degree ended 4 rivet strips o body sheet 2 by the 4 cab steps go where? Or are they spares?

7. The two etched brass cab spectacle plates - are they intended to be soldered together for strength?

8. Presumably the extra pressure gauge is in case it isn’t located as per the rhs one?

I hope you don’t think I’m being picky. You’ve done a grand job! Perhaps the hand rests are a bit too fine as the end eyes have virtually disappeared.

I remember doing something like that with the first shot at Dieppe. I decided then that if people wanted them superfine it was a case of them needing to file them down!

Mike

Hi Mike

No worries.

- Picture on page 2 and 4 of the instructions look like slightly curved copings. GA plans were a bit indistinct so I have drawn straight corners but slightly larger than needed to allow for final fitting.

- Either solid rods for no compensation/springing or pivot on the knuckle as per prototype. Or parts from the both if you want to pivot on the crankpin.

- Depends on your curves, nearer for prototype, further for radius 2.

- On the GA these seem to connect to the water cut off pivot wires. They fit below the footplate in line with the water hoses from the tender to the loco. If you are fitting these – not supplied – they could be used down there in the gloomy bit!

- Between one side of the top of the motion plate and the extended cab side ? Yes.

- On Loco body parts location 2 diagram, these are arrowed. They form the corner rivet strip at right angles to the long underfootplate rivet strip with the short ends at right angles and fit up against the front buffer beam or the rear drag beam as appropriate, after these parts are fitted.

- Yes. It gets the rims on both front and rear. The pressure guage is tot he rear.

- Extra is if you can use the resin cab. I have one out of 12 that seemed perfect, rest a bit ripply. I am expecting most people to use the etched cab.

Hope that is okay. I am around for the next 12 weeks if you need ought else!!

Cheers

Ian

Thanks Ian

The item at no6 - I see the arrows in the rhs diagram on Loco Body Parts Location 2 sheet - they’re arrived from the mainly red diagram of Body Sheet 1 - from the rear end of the cab step back on the outside frames over location on the middle diagram. I get that.

The ones I meant are on the lhs (more white) diagram of Body Sheet 2. The 4 individual steps are arrowed, but the two little rivet strips with 4 rivers and 45degree but off end aren’t. Nor are the two just above the stage beam and below the outside frame backing fold-down strips - one green arrow goes right across one, but from the outer axlebox fold-ups to the solid chassis axle cut out pieces in the middle.

Mike

Hi Mike

Got you now! They are not used either. They were going to be part of the cylinder cover/frames in front of the smokebox and I forgot to remove them. The other parts are to represent the firebox/footplate rivet strip and are shown as such on the next page in diagram Loco Body Parts Location 3 although they do look like they are pointing to the reversing link!

Cheers Ian

Thanks Ian that clears that up.

I’m taking the opportunity to annotate the instructions as the builder was rained off the garage roof today, so no truss and rafter building for me today. Garage is a wet mess! I hope it’s too cold for rust to set in! Tarpaulins were got on yesterday just after the rain started!! Bin. Bags are “protecting” the machine beds!

Btw, on the loco and tender drag beams, there’s a folding end ...? We’re they timber?