I am cracking on with the instructions and thought I should post a couple of the drawings that will be part of the instructions.

These show the etched parts in a red/white combo; grey is the printed resin parts and yellow are the bits of wire, handrail knobs, bearings/hornblocks that I will not be supplying. I asked a couple of people about this and was told by both that they replace the bearings with hornblocks anyway, but they had different preferences for those and that the wire and handrail knobs were not a problem as they always have some in stock. It saves an enormous amount of time and money if I don't supply those parts, and allows me to keep the price to £100.

The alternative versions for the loco springs are shown behind and to the left of the body parts. As are the different types of smokebox door dart, safety valve, chimney, sand boxes with operating links, whistle, cab side sheets, smokebox blower control and injectors for the loco, and the alternative springs, rear toolbox and front tool boxes for the tender.

All these are for the Slaughter Standard Goods. I plan to get two other types available later next year; one of the Cudworth types and one with the remaining two different cab sheets. They will be offered in the same format of mixed resin prints/etching.

I am just awaiting the etches for the 4mm version and am printing off the resin components at the moment whilst writing/drawing up the instructions.

The chassis have three widths of spacer on the etches and provision of full compensation is built in with twin side beams provided and location for a single rocking axle also on both the loco and tender chassis. Coupling rods are provided for either using compensation or not.

There will be an inside motion unit available later as a resin print.

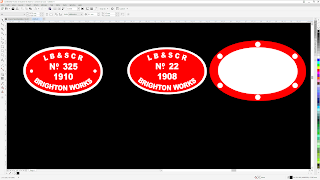

Both Craven and Stroudley number plates will be available when I get the kit etches as they in the same order.

I will be shipping these by the last week of November and then again in February. I am also hoping to have 7mm versions available by the March Windmill Meeting of the Brighton Circle.

Back to the instructions!